The global dental 3D printing market has also witnessed substantial growth, reaching an estimated USD 3.1 billion in 2023.

The landscape of dentistry is undergoing a transformative shift, and at the forefront of this change is the integration of 3D printing technology. According to Envision TEC, a leading 3D printer manufacturer, the sale of 3D printers for the dental industry witnessed a substantial 75% increase in 2016. While traditional manufacturing methods still hold their ground, 3D printing is proving to be a disruptive force. Consequently, offering unparalleled advantages in terms of speed, cost-effectiveness, and customization.

The global dental 3D printing market has also witnessed substantial growth, reaching an estimated USD 3.1 billion in 2023. This dynamic industry is poised for further expansion. Thus, projecting a robust compound annual growth rate (CAGR) of 26.4% from 2024 to 2030. The synergy of cutting-edge technology and a promising market presence has positioned 3D printing as a transformative force in the realm of dental products.

Key Factors Driving Growth

- Advanced Product Development: The design and development of sophisticated products, including invisible aligners and aesthetically pleasing fabrication, contribute significantly to the surge in demand for dental 3D printers.

- Enhanced Aesthetics and Precision: The pursuit of an aesthetic look and precise delivery positioning is pushing the adoption of 3D printing in dentistry. Technology allows for the creation of intricate and customized dental products.

- User-Friendly Procedures: The user-friendliness and simplicity of 3D printing procedures have empowered the dental industry to craft products tailored to the unique dental requirements of individuals. This accessibility promotes widespread adoption among dental professionals.

- Increased Efficiency and Reduced Fabrication Time: Dental 3D printers are enhancing productivity by increasing output and concurrently reducing fabrication time. This efficiency is a significant driver for the adoption of 3D printing technologies in the dental landscape.

- Digitalized Workflow for Customer Satisfaction: The digitalized workflow not only streamlines the production process but also addresses procedural discomfort, ultimately elevating customer satisfaction levels. This transition to digital workflows marks a significant advancement in dental technology.Top of Form

A Paradigm Shift in 3D Printing Manufacturing

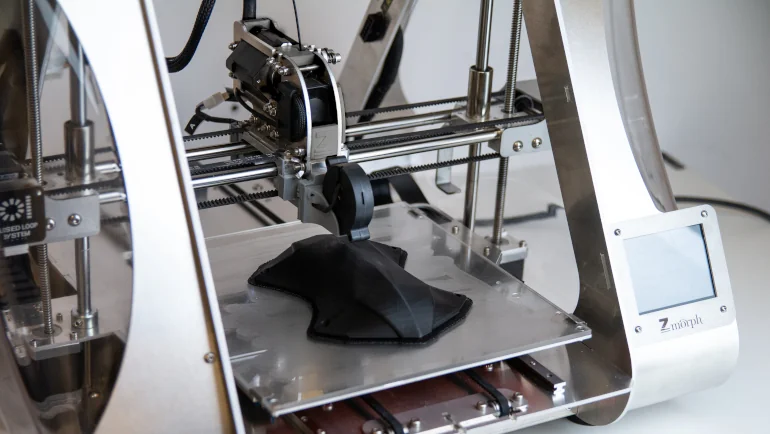

Traditionally renowned for its applications in aerospace, design, and defense, 3D printing is carving a distinct niche for itself in dentistry. The key to its transformative power lies in its ability to facilitate rapid prototyping without the inherent risks associated with conventional methods. This cutting-edge innovation allows for the construction of dental equipment parts at an accelerated pace and significantly lower costs.

Modeling and Customization Made Effortless

One of the remarkable features of 3D printing is its user-friendly nature. Unlike complex traditional manufacturing processes, operating a 3D printer doesn’t require a steep learning curve. This simplicity translates into enhanced customization capabilities for dentists and their practices.

For crafting dental prosthetics, a dentist can seamlessly scan the patient’s mouth cavity. The dentist transfers the data to an application, and with a simple click, he or she can tailor a design that is ready for printing. If they need additional modifications, they can implement it without the need for a complete overhaul of the device.

Enhanced Convenience for Patients

Traditionally, the creation of dental prosthetics involved taking an impression of the patient’s mouth using paste or impression compound, which was then sent to a manufacturer. 3D printing brings a revolutionary change, offering patients a more comfortable and convenient experience. The process is not only quicker but also eliminates the susceptibility to distortion associated with traditional methods.

3D printing finds application in various dental prosthetics, including dental crowns, bridges, implants, dentures, E-Gum (Flexible Gingiva Mask), bite splints, and night guards.

Cost-Effectiveness Unleashed

The high costs associated with setting up and maintaining dental laboratories contribute to the overall expense of dental procedures. However, 3D printing presents a cost-effective alternative for both dentists and patients. While dentists may initially invest in a top-model printer, it’s a one-time cost that pales in comparison to the ongoing expenses of running a traditional dental lab.

This cost-effectiveness has even empowered individuals to explore unconventional applications of 3D printing, as seen in the case of a 24-year-old college student from the New Jersey Institute of Technology, who made headlines for crafting his own braces using a 3D printer.

Reviving Manufacturing Jobs

Dental laboratories, facing competition from low-cost Asian manufacturers, have experienced a decline in business. The number of Certified Dental Lab technicians dropped by 8% between 2010 and 2014. However, the rise of 3D printing is poised to reverse this trend. Dentists are increasingly adopting this technology, sparking a resurgence in manufacturing jobs within the dental industry.

Sirona Primeprint 3D Printing Machine

The Sirona Primeprint 3D printing machine emerges as a game-changer. Thus, reshaping the landscape of dental practices. Consequently, this cutting-edge device redefines precision, efficiency, and customization, seamlessly integrating into modern workflows.

- Precision Redefined: The Sirona Primeprint introduces a new standard of precision in dental product development. Its advanced printing capabilities enable the production of intricately detailed and precisely customized dental prosthetics. As a result, ensuring that each product meets the exacting standards of modern dentistry.

- Effortless Workflow Integration: Engineered with dental professionals in mind, the Sirona Primeprint effortlessly integrates into existing workflows. Its user-friendly interface streamlines the printing process. Thereby, optimizing efficiency without compromising on quality. This ensures a seamless transition for dental practices adopting this revolutionary 3D printing machine.

As the dental industry embraces transformative technologies like the Sirona Primeprint, dental professionals can anticipate a paradigm shift in their approach to product design, development, and overall patient satisfaction.

Future Outlook

The trajectory of the 3D printing market is poised for an upward surge. Thus, it is fueled by continuous technological advancements and an increasing focus on precision, customization, and efficiency in dental procedures. As the industry embraces these transformative technologies, dental professionals are expected to witness a paradigm shift in their approach to product design, development, and overall patient satisfaction.

As the sales of 3D dental printers continue to soar, dentists gain further encouragement to explore the viability of incorporating 3D printing into their practices. For inquiries or to assess the applicability of 3D printers for your dental needs, contact Dr. Suffoletta at 702-671-0001. The future of dentistry is evolving, and 3D printing is leading the way.